CNC Automatic Insulating Glass Aluminum Spacer Bending MachineProduct description of Automatic Aluminum Spacer Bending Machine Automatic Aluminum Spacer Bending Machine is a special equipment for the production of Insulating glass aluminum frame, replacing the traditional manufacturing process.

Contacta ahora

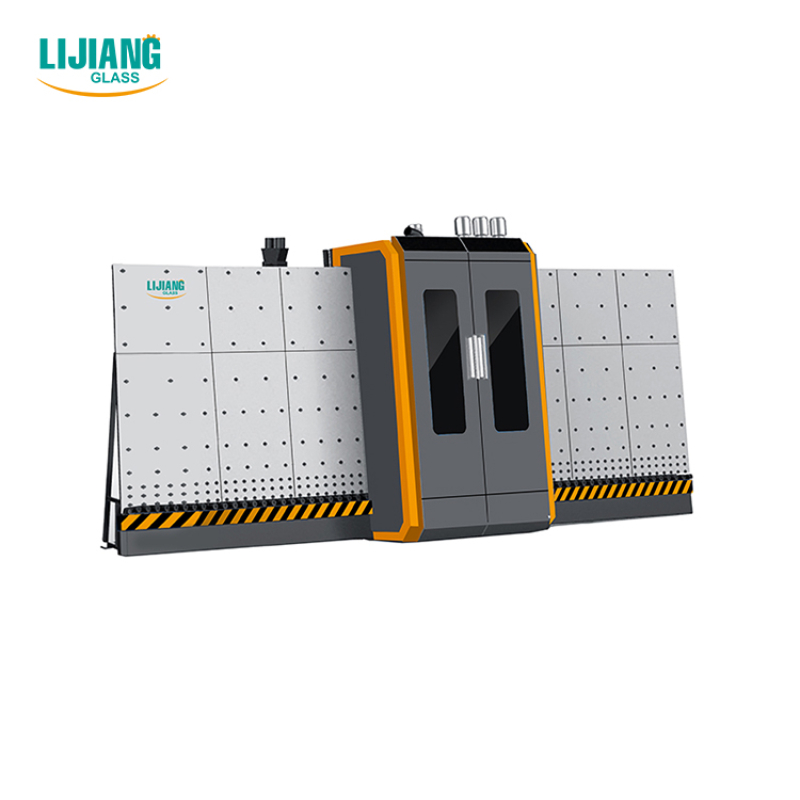

AUTOMATIC GLASS WASHING AND COMBINING LINE WITH HYDRAULIC PANEL PRESS 3300*7000 mmAutomatic glass washing and combining line with hydraulic panel press can assemble and press double, triple or structural (step, facade) insulating glass units.Model of Standard line: LJZB3370PERFORMANCE:1.The whole line use Germany Siemens PLC control system,touch screen interface,Easy and convenient operation .2.In the first section you can see the sensor , It can detect the film of Low-e glass.(At the same time, it can also automatically measure the thickness of the glass )15-30 mm.3.3 pairs of soft brushes ca

Contacta ahora

Vertical insulating glass manufacturing line is used for making insulating glass for houses, home home home windows and doorways, moreover for deliver, fridge, freezer and so forth. this ig line consists of glass washing and glass urgent system, it may make double / triple glazing glass, for sides step glass.

Contacta ahora

Vertical insulating glass production line is used for making insulating glass for homes, domestic domestic home windows and doorways, furthermore for supply, fridge, freezer and so forth. this ig line consists of glass washing and glass pressing gadget, it can make double / triple glazing glass, for sides step glass.

Contacta ahora

Description of Glass Sandblasting MachineGlass automatic sandblasting machine control by the PLC, suitable for processing 5-40mm thickness of flat glass to different kind of frosting patterns . The transmission control by the photo switch and limit switch automatically. Glass conveys by the belt, and the guns driven by chain so that can be move up and down for sandblasting (the distance can be adjusted according to the requirement). Stable transmission, high efficiency and easy maintenance of the chain system.

Contacta ahora

PERFORMANCESix sets of servo motors, British TRIO systemInlet-outlet with two-direction , 4 directions are availableAutomatically measure glass sizeAutomatically distinguish Low-E filmThe width of edge deletion is adjustablePLC control system, touch screen interfaceIntelligent control system, can recognize batch processing Deleting shaped glass Recognize Low-E fil

Contacta ahora

ApplicationLJDM2545 clever vertical facet deleting gadget is used to delete the brink movie of the Low-e glass. The glass facet deleting gadget adopts imported servo manage system, positioning appropriately with easy operation. High high-satisfactory grinding wheels are durable, can produce neat and delightful grinding crack.

Contacta ahora

PERFORMANCE of Vertical Insulating air-floating Glass Processing LineAir floating back plate , to avoid the wheel scraching the glass and leaving wheel marksTwo pieces of IGU could be pressed and filled gas in once time, high work efficiency Gas filling in pressing,automatic filling the glass in different areas according to the size of glassGermany Siemens PLC control system, touch screen interface Automatic identification of coated and Low-E glass3 pairs of soft brushes can wash online and offline Low-E glass The washing machine adopts SS material and waterproof deviceWater tan

Contacta ahora

Smart Vertical Edge Deleting Machine LJCM2545 Main feature• Two-way glass access• Delete double and triple silver low-e glass• Automatically measure glass size• Automatically distinguish low-e surface• Edge deletion is adjustable• The head can be rotated 360°• Safe and full automatic device• PLC control system, touch screen interface • Six servos control system• Intelligent control system, can recognize batch processing Technical dataMax. glass processing size2500*4500mm Min. glass pr

Contacta ahora

Big Rotating Table For Manual Sealing Pump MachineIntroduction of the Rotating table machineRotating table is used to help coat the second sealants for insulating glass, used together with the manual sealing pump machine. It is a small manual machine with cheap price. There is a sucker in the middle of the machine to support the glass. and the wheels are used to rotate the glass when coating the four sides of the glazing glass.

Contacta ahora

KTLQ-2500 Vertical Glass Washing MachineKTLQ-2500 glass washing machine can wash maax glass of 2500mm*3500mm, more large size and less size can be optional. - Self-Diagnosis system with touch screen on computer. - Stainless steel washer with 8 ( 6 ) brushes, soft brushes from MONFORTS of Germany, hard brushes automatically open when Low-E glass input. - Rotate speed of brush frequency control. (optional) - Stainless steel air knife is automatically adjustable according to glass thickness, Max thickness to 19mm.

Contacta ahora

LJTJ2025 Automatic Insulating Glass Coated Glass Double Component Sealing Robot MachineProduct DescriptionLJDM2545 Smart Vertical Edge Deleting MachineLJDM2545

smart vertical edge deleting machine is used to delete the edge film of

the Low-e glass. The glass edge deleting machine adopts an imported servo

control system, positioning accurately with smooth operation. High-quality grinding wheels are durable and can produce neat and beautiful

grinding cracks.

Contacta ahora

Vertical insulating glass production line is used for making insulating glass for homes, home home windows and doorways, moreover for supply, fridge, freezer and so forth. this ig line includes glass washing and glass urgent gadget, it is able to make double / triple glazing glass, for facets step glass.

Contacta ahora

Description of insulating glass production lineWhat does insulating glass production line do? Insulating glass production line is mainly for glass cleaning, plate pressing and inflation.

Contacta ahora

Vertical automatic insulating glass production line LJBZ2535Main characteristics of insulating glass production line:• Extra long insulating glass can be compressed twice• The insulating glass production line adopts servo torque pressing glass• The pressing plate adopts adjustable screws to ensure lasting pressing and high precision• With precise adjustable front platen mechanism• The system of insulating glass production line supports fault information diagnosis• The platen can be opened up to 400mm wide for easy maintenance• Automatic insulating glass production line is suitable for the prod

Contacta ahora

Common problems and solutions in the production of insulating glassIn the production process of insulating glass, the frequently occurring problems are:1. When butyl rubber is extruded, burrs and not smooth

2. Butyl glue does not stick to aluminum strips and glass and loses its stickiness

3. After the second seal is completed, a cold flow of butyl rubber appears after some time

4. When butyl rubber is extruded, there will be glue breaking and blockage...Frequent problems in finished hollow glass products:1. Fogging inside the hollow glass

2. Condensation of hollow glass

3.

Contacta ahora

LJBZ2025G vertical hollow glass flat pressure production line can complete the following functions: glass cleaning, aluminum frame placement, ordinary double glass, ordinary three glass, double glass aeration and three glass aeration.LJBZ2025G is a special equipment in aluminum hollow glass production.

Contacta ahora

LJBZ2025 Automatic Vertical Laminated Insulating Glass Double Glazing Production Line Details DisplayThe whole insulating glass production line usually includes 7 parts: (from right to left)1, The Loading section(with Low-E checking) 2, The washing and drying section(can wash Low-E glass) 3, The conveyor section 4, The checking and assembly section 5, The conveyor measure, and the sensor section 6, The press part with gas filling 7, The unloading section.The second part: is the washing and drying section.In this glass cleaning section, there are thre

Contacta ahora

APPLICATIONLijiang Production Line adopts the latest production technology, its main purpose is to create high-end quality, provide customers with the latest production technology and a complete set of product solutions, improve production efficiency, save production costs, and generate maximum benefits.At present, Lijiang hollow glass production line mainly adopts the new technology of air flotation to transport glass. This new technology is to prevent glass from being contaminated by wheels and leaving marks, so as to improve the quality of IG production. Detailed description1.

Contacta ahora

Vertical insulating glass production line is used for making insulating glass for homes, home windows and doorways, additionally for deliver, refrigerator, freezer and so forth. this ig line includes glass washing and glass pressing system, it is able to make double / triple glazing glass, for facets step glass.

Contacta ahora

Production Description of the product: The product can load of 600 kg. It is able to be used with out outside electricity deliver. the suction, release and rotation of the suction cup are all managed by remote control. each suction cup has a separate switch which may be used as required, and the suction cup holder has a telescopic rod which can be hooked up or removed as required.

Contacta ahora

Vertical insulating glass manufacturing line is used for making insulating glass for houses, domestic domestic domestic home windows and doorways, furthermore for deliver, fridge, freezer and so forth. this ig line includes glass washing and glass pressing system, it is able to make double / triple glazing glass, for aspects step glass.

Contacta ahora

Two-component glue coating machine is suitable for the last procedure of insulating glass production line, mainly used for two-component polysulfide glue, two-component silicone hollow glue coating.

Contacta ahora

ApplicationThis gadget changed into designed with the aid of using superior generation from overseas and internal of China. It is unique gadget used for spreading the two-thing polysulphide glue and/or two-thing silicone shape glue for the aluminum kind insulating glass or curtain wall glass.A and B pump undertake Korea emblem HASCO.So it may make sure the dependable working-impact.Special and handy blended tool can make sure the excessive first-class blending of the two-thing polysulphide glue and/or two-thing silicone shape glue.

Contacta ahora