1. What is the role of aluminum strip bending machine? Why do aluminum bars bend?Aluminum strip bending machine is mainly used for continuous bending of insulating glass aluminum strip. Aluminum strip bending can improve the sealing performance of insulating glass and its appearance is better2. What kinds of rigid insulating glass spacer are there?

Contacta ahora

Professional Customized Auto Insulating Glass Aluminum Spacer Strip Bar Bending Machine Could Foldable Special Shape BendingProduct DescriptionLJZW2020 Automatic Aluminum Spacer Bar Bending MachineJinan LIJIANG Glass Automatic Insulating Glass Spacer Bar Bending Machine is the special equipment for making aluminum frames of insulating glass, which replaces the traditional fabrication techniques.

Contacta ahora

Main featureSpacer frame transport Easy operating, simple and flexibleTechnical dataPower supply380V 50HzTotal power0.18kwDimension2520*3012*3000mm

Contacta ahora

CNC automatic hollow glass aluminum spacer bending machineProduct description of automatic aluminum spacer bending machineAutomatic aluminum spacer bending machine LJZW2020Jinan Lijiang Glass automatic hollow glass aluminum spacer bending machine is a special equipment for the production of hollow glass aluminum frame, replacing the traditional manufacturing process.

Contacta ahora

• It is used for cutting aluminum strip• Allowed to cut many spacers,keep high efficiencyPower supply380V 50HzTotal power0.55kwDimension5000*1050*415mm

Contacta ahora

Automatic Aluminum Spacer Bending Machine LJZW2020Automatic spacer bending machine is a special equipment for making aluminum frames of insulating glass, which replaces the traditional fabrication technology. This equipment can make a variety of convex polygonal aluminum frames by one aluminum strip in one time, thus strengthening the strength of the aluminum frame, making the sealing effect of the insulating glass more betterTechnical dataMax.bending size2000mm*2000mm (2500mm*2500mm)Min.bending size250mm*200mmAluminum spacer width5.5-27mmDimensional error±0.5mmA

Contacta ahora

Common problems and solutions in the production of insulating glassIn the production process of insulating glass, the frequently occurring problems are:1. When butyl rubber is extruded, burrs and not smooth

2. Butyl glue does not stick to aluminum strips and glass and loses its stickiness

3. After the second seal is completed, a cold flow of butyl rubber appears after some time

4. When butyl rubber is extruded, there will be glue breaking and blockage...Frequent problems in finished hollow glass products:1. Fogging inside the hollow glass

2. Condensation of hollow glass

3.

Contacta ahora

Automatic Spacer Bending Machine LJZW2020 Application27A aluminum bending machine is a special equipment for making aluminum frames of insulating glass, which replaces the traditional fabrication technology.Technoform glass bending machine can make a variety of convex polygonal aluminum frames by one aluminum strip in one time, thus strengthening the strength of the aluminum frame, making the sealing effect of the insulating glass more better. Technical Data Max.bending size2000mm*2000mm (2500mm*2500mm)Min.bending size250mm*200mmAluminum spa

Contacta ahora

ApplicationAutomatic spacer bending machine is a special equipment for making aluminum frames of insulating glass, which replaces the traditional fabrication technology. This equipment can make a variety of convex polygonal aluminum frames by one aluminum strip in one time, thus strengthening the strength of the aluminum frame, making the sealing effect of the insulating glass more better. Equipment detailsAdopt Siemens PLC control systemThere are 4 Siemens servoAdopt 12 sets of racks which could storage more different sizes of spacers.

Contacta ahora

PERFORMANCEAdopt the servo manipulate feeding machine, spacer body length may be adjusted with an accuracy of 0.1 mm/mCNC bending perspective manipulate machine with adjustable accuracy of 0.1°Set up 4 corporations of spacers garage unitsAluminum bar with a couple of sizes may be decided on at willAutomatically alter the bending pace in keeping with the dimensions of the aluminum body to keep away from the deformation of the big body and make sure the excessive pace and continuity of the small bodyAutomatic continuous connection of spacer, cutting spacer, avoidance of spacer bar jointNo materi

Contacta ahora

PERFORMANCESix units of servo motors, British TRIO systemInlet-outlet with two-direction , four instructions are availableAutomatically degree glass sizeAutomatically distinguish Low-E filmThe width of part deletion is adjustablePLC manage system, contact display screen interfaceIntelligent manage system, can apprehend batch processing Deleting shaped glass Recogn

Contacta ahora

PERFORMANCESix sets of servo motors, British TRIO systemInlet-outlet with two-direction , 4 directions are availableAutomatically measure glass sizeAutomatically distinguish Low-E filmThe width of edge deletion is adjustablePLC control system, touch screen interfaceIntelligent control system, can recognize batch processing Deleting shaped glass Recognize Low-E fil

Contacta ahora

We offer world-class array of SEMI-AUTO Aluminum Frame Transfer Machine that are treasured for high strength and durable standards. Our entire product range is quality tested on varied pre-determined parameters thereby delivering flawless product line.• Spacer frame transport• Easy operating, simple and flexiblePower supply380V 50HzTotal power0.18kwDimension2520*3012*3000mm

Contacta ahora

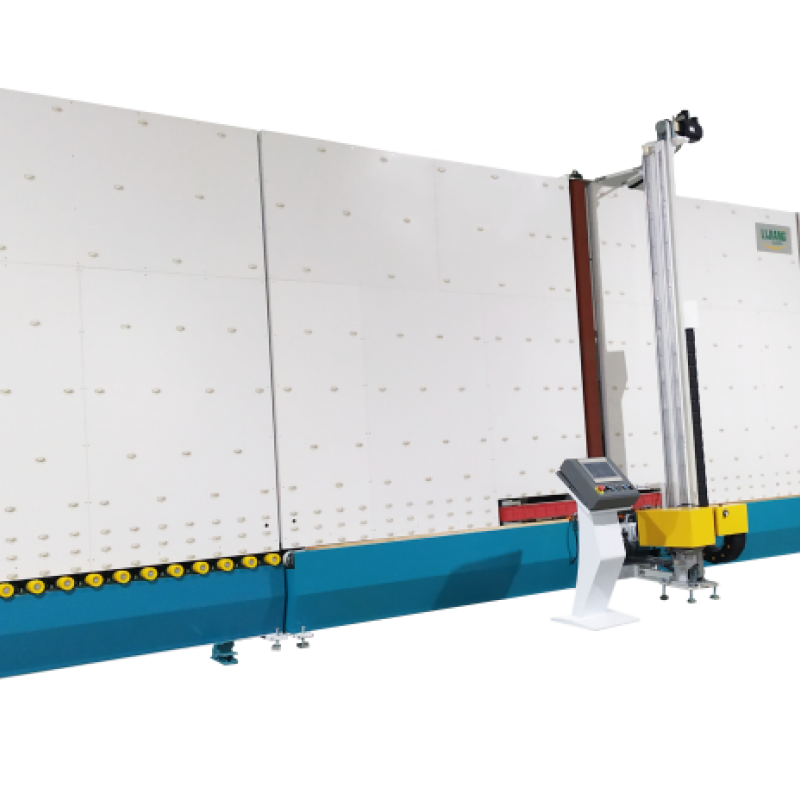

LJBZ2025G vertical hollow glass flat pressure production line can complete the following functions: glass cleaning, aluminum frame placement, ordinary double glass, ordinary three glass, double glass aeration and three glass aeration.LJBZ2025G is a special equipment in aluminum hollow glass production.

Contacta ahora

Automatic aluminum strip bending machine performance introductionAluminum bar bending machine adopts servo control feeding system, the size of spacer frame can be adjusted, the accuracy can reach 0.1mm /mNumerical control bending Angle control system of aluminum bar bending machine, precision can be adjusted 0.1°Four groups of spaced storage units can be set up for the aluminum bar benderAluminum bar with multiple sizes can be selected at willAutomatically adjust the bending speed according to the size of the aluminum frame to avoid the deformation of the large frame and ensure the high speed

Contacta ahora

ApplicationLJTB 01 Butyl extruder gadget is used for spreading aluminum spacer frames frivolously with warm soften butyl. The butyl extruder makes use of big electric manage panel which makes the operation greater less complicated than before. The conveyor of aluminum is managed through frequency converter. The pace may be adjusted from 0m/min to 47m/min, it's far the quickest pace in China till now. The butyl extruder may be very famous with energy-saving. Its squeezing machine adopts pneumatic and hydraulic supercharging machine, which makes the squeezing strain greater strong.

Contacta ahora

The type of LJCJ01 smart insulating glass gas filling machine is special equipment for inflatable hollow glass. The device uses microcomputers and imported sensor to form a closed loop control system, high degree of intelligent equipment, precise control, pneumatic adjustable concentration, high charging efficiency, the operation is simple.

Contacta ahora

Automatic Horizontal Insulating Glass Aluminum Strip Bar Bending Machine with Touch Screen Interface and Four Storage TroughsProduct DescriptionLJZW2020 Automatic Aluminum Spacer Bar Bending MachineJinan LIJIANG Glass Automatic Insulating Glass Spacer Bar Bending Machine is a special equipment for making aluminum frames of insulating glass, which replaces the traditional fabrication technology.

Contacta ahora

Smart insulating glass gas filling machine is special equipment for inflatable hollow glass. The device uses microcomputers and imported sensor to form a closed loop control system, high degree of intelligent equipment, precise control, pneumatic adjustable concentration, high charging efficiency, the operation is simple.

Contacta ahora

Two-component glue coating machine is suitable for the last procedure of insulating glass production line, mainly used for two-component polysulfide glue, two-component silicone hollow glue coating.

Contacta ahora

Automatic spacer bending machine is used for aluminum frame of insulating glass.Automatic aluminum spacer bending machine is controlled by PLC.

Contacta ahora

Main featureIt is used for slicing aluminum stripAllowed to reduce many spacers,maintain excessive efficiencyTechnical dataPower supply380V 50HzTotal power0.55kwDimension5000*1050*415mm

Contacta ahora

1. Vertical Edge Deleting Machine UsageVertical Edge Deleting Machine LJCM2545 is used to remove low-e film from edges of the glass. It can be connected to the insulating glass production line and is necessary equipment in insulated glass processing. Speed of transmission and grinding are adjustable, and the machine is equipped with automatic cleaning system.

Contacta ahora

1. UsageLJBZ2500PG Vertical insulating glass production line has the following functions: Washing glass, Installing aluminum frame, Pressing normal IG units, Pressing double IG units, Pressing double three-layers IG units. LJBZ2500PG is a special equipment in the production of insulating glass with aluminum strip, which has so many advantages, such as small footprint, high efficiency, reliable performance, convenient maintenance and so on.

Contacta ahora