Hot Melt Adhesive Insulating Glass Production Line Beam Tape Coating Equipment Butyl Extruder Tape Coating MachineProduct DescriptionJinan LIJIANG Glass LJTB01 Butyl Extruder MachineThe type of LJTB01 butyl extruder machine is used for spreading aluminum spacer frames evenly with hot melt butyl. LJTB01 butyl extruder machine use large electrical control panel which makes the operation more easier. The conveyor of aluminum is controlled by frequency converter, and the speed can be adjusted from 0m/min to 47m/min, which has the fastest speed in China.

Contacta ahora

LJTB01 Butty Extruder Machine ApplicationSealant extrusion coating machine is used for spreading aluminum spacer frames evenly with hot melt butyl.Spreading Butyl Extruder Machine use large electrical control panel which makes the operation more easier. The conveyor of aluminum is controlled by frequency converter, and the speed can be adjusted from 0m/min to 47m/min, which has the fastest speed in China. Hydraulic hot melt butyl machine is very popular with energy-saving.

Contacta ahora

Hot Melt Adhesive Insulating Glass Production Line Beam Tape Coating Equipment Butyl Extruder Tape Coating MachineProduct DescriptionJinan LIJIANG Glass LJTB01 Butyl Extruder MachineAutomatic butyl extruder LJTB01 is used for hot melt butyl to evenly smear aluminum spacer frame. Automatic butyl extruder type LJTB01 adopts large electrical control panel for more convenient operation.

Contacta ahora

Jinan LIJIANG Glass LJTB01 Butyl Extruder MachineThe type of LJTB01 butyl extruder machine is used for spreading aluminum spacer frames evenly with hot melt butyl. LJTB01 butyl extruder machine use large electrical control panel which makes the operation more easier. The conveyor of aluminum is controlled by frequency converter, and the speed can be adjusted from 0m/min to 47m/min, which has the fastest speed in China. LJTB01 butyl extruder machine is very popular with energy-saving.

Contacta ahora

Main featureIt is used for storing the gun when manual glue gun stop work during the process of gluing insulating glassStoring at low temperature,to prevent sealant solidifyApply to polysulfide and siliconeCan be effectively reduced waste when cleaning the glueTechnical dataMax refrigerating temperature70ºCMin heating temperature-40ºCTotal power3.8kwRefrigerating<150minOverall dimension1550*60*1300mm

Contacta ahora

Lijiang butyl extruder machine is used to apply hot melt butyl to the aluminum spacers of insulating glass evenly. The use of large electrical control panel makes the operation easier. The conveyor of aluminum is controlled by frequency converter, and the speed can be adjusted from 0m/min to 47m/min. The squeezing system adopts pneumatic and hydraulic supercharging system, which makes the squeezing pressure more stable. The machine is energy-saving. The dispensing cylinder uses rotate supporting system and this makes the refill of butyl easier.

Contacta ahora

Two-component glue coating machine is suitable for the last procedure of insulating glass production line, mainly used for two-component polysulfide glue, two-component silicone hollow glue coating.

Contacta ahora

LJTB01 butyl extruder machineThe type of LJTB01 butyl extruder machine is used for spreading aluminum spacer frames evenly with hot melt butyl. LJTB01 butyl extruder machine use large electrical control panel which makes the operation more easier. The conveyor of aluminum is controlled by frequency converter, and the speed can be adjusted from 0m/min to 47m/min, which has the fastest speed in China. LJTB01 butyl extruder machine is very popular with energy-saving. Its squeezing system adopts pneumatic and hydraulic supercharging system, which makes the squeezing pressure more stable.

Contacta ahora

ApplicationLJTB 01 Butyl extruder machine is used for spreading aluminum spacer frames evenly with hot melt butyl. The butyl extruder uses large electrical control panel which makes the operation more easier than before. The conveyor of aluminum is controlled by frequency converter. The speed can be adjusted from 0m/min to 47m/min, it is the fastest speed in China until now. The butyl extruder is very popular with energy-saving. Its squeezing system adopts pneumatic and hydraulic supercharging system, which makes the squeezing pressure more stable.

Contacta ahora

PERFORMANCEThe coating glue velocity can attain forty seven m/ minSaving glue via way of means of as compared with normal machine.

Contacta ahora

PERFORMANCEThe coating glue speed can reach 47 m/ minSaving glue by compared with ordinary machine.

Contacta ahora

PERFORMANCEPLC control system, touch screen interfaceVariable Frequency control systemArc frame coating structureImported pneumatic and hydraulic supercharging systemAutomatic centering and clamping structureAdopt five steps to control conveyPreheating function,glue cylinder limit function,alarm systemPARAMETERSqueeze pressure 10-18MPaTemperature 110〜140°CAluminum spacer width 5.5-26.5mmSpeed0-40m/minDiameter of butyl cylinder 200mmAir supply Flow 0.4m3/minAir pressure > 0.6MPaVoltage 380V 5KW 50HzDimension 3000*700*1200mmWeight650kg

Contacta ahora

PERFORMANCEUse cylinder to provide powerThe famous sealant gun in China, stainless steel mixerHigh pressure protect deviceAnti-back flow control structureMixed rate detector can control the rate of two kinds of gluePARAMETERWorking air pressure>0.6MPaSealant spreading pressure15-20MPaSealant volume4L/minDiameter of A/B sealant570mm/280mmMixed rate6:1-14:1Air supplyFlow 0.8m3/minAir pressure>0.8MPaOverall dimension1700*1260*1900mmWeight600 kg

Contacta ahora

• PLC manage machine, contact display interface• Automatically discover the width of aluminum bar, the glue nuzzle may be automated adjust• The vital a part of the hydraulic machine the usage of German imports of additives to make certain that the plastic frivolously full• Fast preheat, enhance paintings efficiency Squeeze pressure10-18MPaTemperature 110~140℃ Aluminum spacer width6A - 27A Speed 5-47m/min Diameter of butyl cylinder200mm Air supply0.4m³/minAir pressure≥0.6MPaTotal power 380V, 5.7KW,50HZDimension 2800×700×900mm(L×W×H)weight650k

Contacta ahora

Main featureClean working, simple and flexibleIt is used for solving and rotating glass while guide coating the outside of ig glassThe middle sucker is suitable for small pieces of glass,but,extra guide body is for big portions of glassTechnical dataPower supply380V 50HzTotal power0.37kwOperating dimension1500*1500mmDimension600*550*985mmWeight75/48kg

Contacta ahora

Main feature Easy operating, easy and flexibleIt is used for solving and rotating glass whilst guide coating the outdoor of IG glassThe center sucker is appropriate for small portions of glass,however,greater guide body is for huge portions of glassTechnical dataPower supply380V 50HzTotal power0.37kwOperating dimension1500*1500mmDimension600*550*985mmWeight75/48kg

Contacta ahora

Automatic Butyl Extruder Machine used for Spreading Aluminum Spacer Frames Insulated Glass ProcessingProduct DescriptionAutomatic LJTB01 Butyl Extruder MachineThe

type of LJTB01 butyl extruder machine is used for spreading aluminum

spacer frames evenly with hot melt butyl. LJTB01 butyl extruder machines

use a large electrical control panel which makes the operation easier. The conveyor of aluminum is controlled by a frequency converter,

and the speed can be adjusted from 0m/min to 47m/min, which has the

fastest speed in China.

Contacta ahora

Main featureIt is used for storing the gun while guide glue gun prevent paintings throughout the technique of gluing insulating glassStoring at low temperature,to save you sealant solidifyApply to polysulfide and siliconeCan be efficiently decreased waste while cleansing the glueTechnical dataMax refrigerating temperature70ºCMin heating temperature-40ºCTotal power3.8kwRefrigerating<150minOverall dimension1550*60*1300mm

Contacta ahora

Main featureClean working, easy and flexibleIt is used for fixing and rotating glass at the same time as manual coating the out of doors of ig glassThe center sucker is appropriate for small portions of glass,but,more manual frame is for huge quantities of glassTechnical dataPower supply380V 50HzTotal power0.37kwOperating dimension1500*1500mmDimension600*550*985mmWeight75/48kg

Contacta ahora

• PLC control system, touch screen interface• Automatically identify the width of aluminum bar, the glue nuzzle can be automatic adjust• The critical part of the hydraulic system using German imports of components to ensure that the plastic evenly full• Fast preheat, improve work efficiency Squeeze pressure10-18MPaTemperature 110~140℃ Aluminum spacer width6A - 27A Speed 5-47m/min Diameter of butyl cylinder200mm Air supply0.4m³/minAir pressure≥0.6MPaTotal power 380V, 5.7KW,50HZDimension 2800×700×900mm(L×W×H)weight650kg

Contacta ahora

ApplicationThis gadget changed into designed with the aid of using superior generation from overseas and internal of China. It is unique gadget used for spreading the two-thing polysulphide glue and/or two-thing silicone shape glue for the aluminum kind insulating glass or curtain wall glass.A and B pump undertake Korea emblem HASCO.So it may make sure the dependable working-impact.Special and handy blended tool can make sure the excessive first-class blending of the two-thing polysulphide glue and/or two-thing silicone shape glue.

Contacta ahora

ApplicationThe two-component gluing machine is designed by advanced technology at home and abroad. It is a special equipment for applying two-component polysulfide adhesive and/or two-component silicone structural adhesive to insulating glass or curtain wall glass. A, B pump using Korean HASCO brand, so as to ensure reliable working effect.Special mixing device of two-component gluing machine ensures high quality mixing of two-component polysulfide glue and/or two-component silicone structural glue.

Contacta ahora

Main feature Easy operating, simple and flexibleIt is used for fixing and rotating glass when manual coating the outside of IG glassThe middle sucker is suitable for small pieces of glass,however,extra support frame is for large pieces of glassTechnical dataPower supply380V 50HzTotal power0.37kwOperating dimension1500*1500mmDimension600*550*985mmWeight75/48kg

Contacta ahora

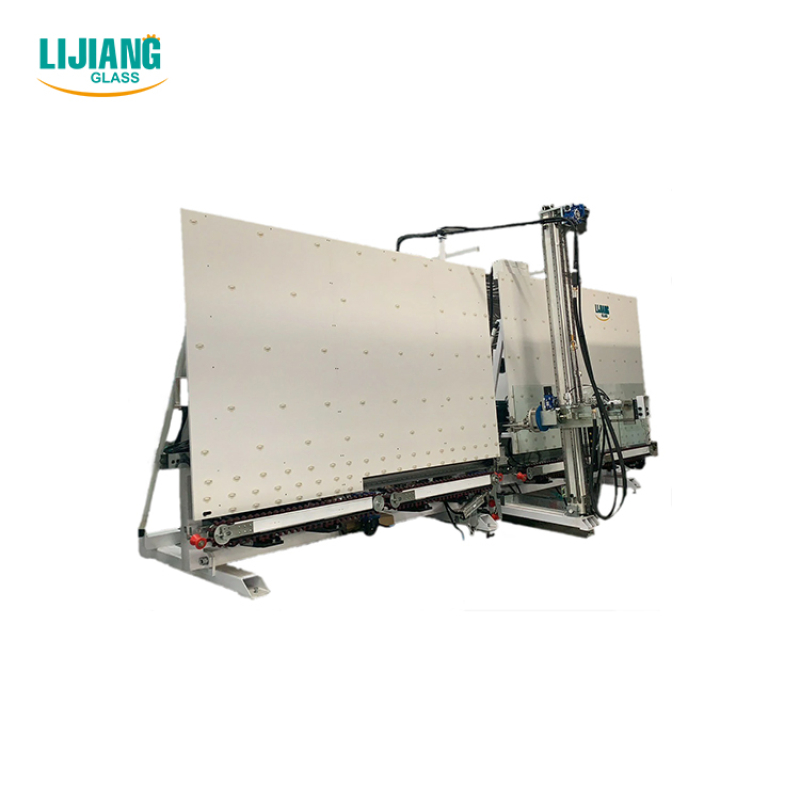

LJTJ2540 Automatic Vertical Insulating Glass Sealing Robot Could Making the Tempered glass is processed into Insulating GlassProduct DescriptionAutomatic Vertical Insulating Glass Sealing RobotJinan LIJIANG Glass Automatic Insulating Glass Sealant Sealing Robot Machine can apply the mixed sealant evenly to the outer channel of the insulating glass through the servo mechanism to help the sealing and bonding performance of the insulating glass.

Automatic Vertical Insulating Glass Sealing Robot Machine could apply the mixed sealant evenly to the outer channel of the insulating glass through the

Contacta ahora